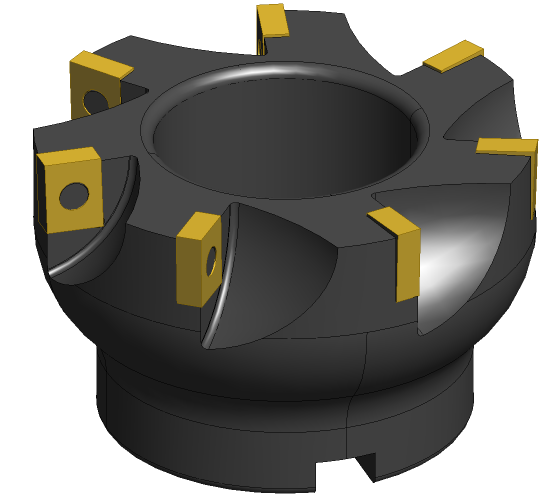

Side And Face Milling Cutter Insert Type

Milling cutters are primarily categorised in side and face milling cutters solid carbide cutter and t slot cutters.

Side and face milling cutter insert type. Inserts for gear milling. Negative inserts for turning outside dimension. Free shipping on eligible orders. We are well known suppliers of all kinds of milling cutters.

R8 fmb22 straight shank arbor 400r face end mill cutter with 4pcs carbide inserts turning tool. The yg 1 ml102 series premium hss side face milling cutter has a staggered tooth design and is made from a high speed steel 5 cobalt substrate. From bore diameter 44 mm. Face milling is the most common milling operation and can be performed using a wide range of different tools.

Cutting width up to 5 26 mm. Also known as indexable face mills replaceable insert face milling cutters remove metal at least two times faster than comparable high speed steel face milling cutters. These cutters are ideal for economic machining of alu. Inserts for routing and pocketing cutter aju type inserts for side milling cutter.

When the cutting edges dull replace the carbide inserts instead of the entire tool. They were the most prominent milling cutters in between 1810 to 1880. You will find cutting teeth on its peripheral area and on its sides. Cutters with a 45º entering angle are most frequently used but round insert cutters square shoulder cutters and side and face mills are also used for certain conditions.

Positive inserts for turning outside. Side and face cutter makes the cutting on one side an easy and efficient process. This type of cutter is available in various sizes and shapes. Cutter heads and side milling cutters with screwed inserts type 314.

Special face and side milling insert tssn tscn tsln. The tools are ideally suited to roughing and finishing operations and are therefore particularly popular in the following sectors. With their sturdy tangential and four edged indexable inserts the newly developed walter xtra tec side and face mills ensure a high machining volume for parting slotting grooving and shoulder milling. Cutting depth t max 5 mm.

These kits include a cutter body inserts wrenches and screws. Special face and side milling insert inserts for milling h bean rails. Available machine type and frequency of operation determine whether an end mill long edge cutter or side and face milling cutter should be used side and face cutters offer the most efficient method for milling large volumes of long deep grooves particularly when horizontal milling machines are used.