Side And Face Cutters Are Used For Making

The basket inquiries you can specify your requirements for the product in the table or you can type in questions for sales representative.

Side and face cutters are used for making. These are the special kind of cutters which are used to create different types of gears. High speed steel scratched numbers make unisto overseas buyers please contact me for postage. Dear customer you have the opportunity to make a preliminary inquiry to this product. Find here online price details of companies selling side face milling cutter.

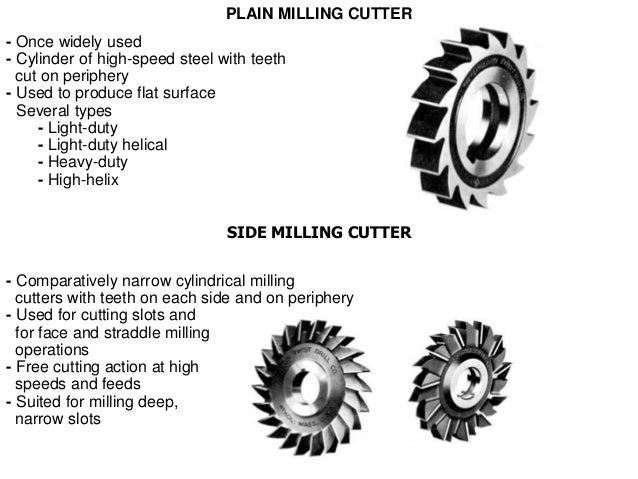

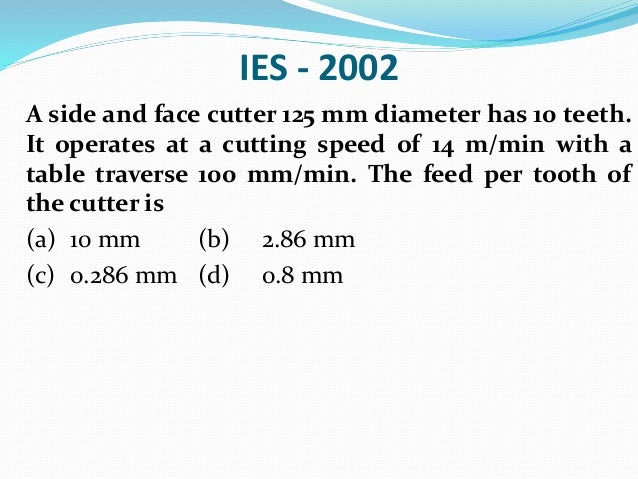

Side and face cutters are designed with cutting teeth on its side as well as its circumference. They are made in varying diameters and widths depending on the application. 4 diam x 1 4 face width straight tooth side milling cutter 1 arbor hole high speed steel uncoated 24 teeth. It is available in varying diameters and widths depend on application.

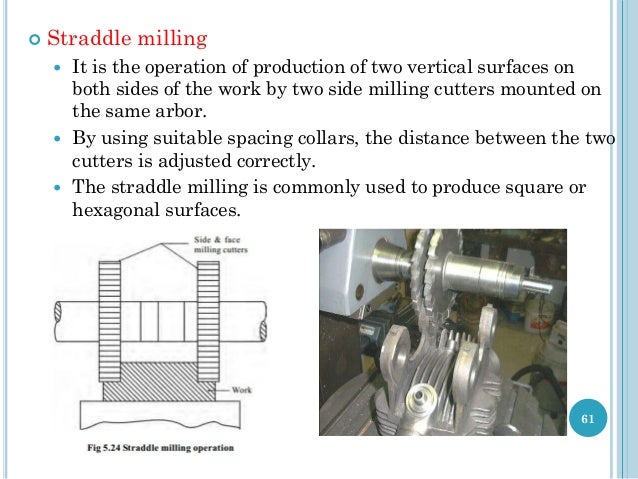

Side or face cutters are manly used to cut slot. The teeth on the side allow the side and face cutters to make unbalanced cuts cutting on one side only without deflecting the cutter as would happen with a slitting saw or slot cutter no side teeth. The teeth on the side allow the cutter to make unbalanced cuts cutting on one side only without deflecting the cutter as would happen with a slitting saw or slot cutter. Msc 73014169 made in usa.

Cutters of this form factor were the earliest milling cutters developed. As the name suggests they are mostly applied in hobbing machines. The teeth on the side allow the cutter to make unbalanced cuts cutting on one side only without deflecting the cutter as would happen with a slitting saw or slot cutter no. Good used type n 10 o sp112 make hss face side milling cutter 4 x 3 4 x 1.

Side and face cutter 2 part interlocking 160 x 32. Hob is machine process of gear cutting. Order goods key cutters side and face milling cutters. This cutter has teeth both its side and circumference.

When the cutting edges dull replace the carbide inserts instead of the entire tool. Side and face cutter makes the cutting on one side an easy and efficient process. They are made in varying diameters and widths depending on the application. Combine a cutter with carbide inserts sold separately to create a face milling cutter also known as indexable face milling cutters.

A cross section of the cutter tooth will generate the require shape on the work piece. They remove metal at least two times faster than comparable high speed steel face milling cutters. Side face cutter selling for a frienditem is used and reasonably old but still functions well. The side and face cutter is designed with cutting teeth on its side as well as its circumference.

Hob cutter is specialist.

.jpg)