Side And Face Cutter Definition

Dear customer you have the opportunity to make a preliminary inquiry to this product.

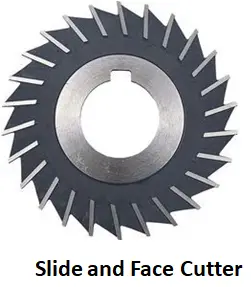

Side and face cutter definition. The basket inquiries you can specify your requirements for the product in the table or you can type in questions for sales representative. They can also be built into a gang to machine more than one surface in the same plane at the same time. Side and face cutters are designed with cutting teeth on its side as well as its circumference. The teeth on the side allow the side and face cutters to make unbalanced cuts cutting on one side only without deflecting the cutter as would happen with a slitting saw or.

Side and face milling cutters can handle long deep open slots in a more efficient manner and provide the best stability and productivity for this type of milling. The yg 1 ml102 series premium hss side face milling cutter has a staggered tooth design and is made from a high speed steel 5 cobalt substrate. The side and face cutters can also be customized to generate required form as per client s description. 1 16 of over 1 000 results for industrial scientific.

The side face cutters we manufacture have gained tremendous appreciation in the market for their host of exclusive features. These are developed using high speed steel of m2 m35 m42 and t42 grades. This type of cutter is available in various sizes and shapes. They are made in varying diameters and widths depending on the application.

The teeth on the side allow the cutter to make unbalanced cuts cutting on one side only without deflecting the cutter as would happen with a slitting saw or slot cutter. They are made in varying diameters and widths depending on the application. Side and face cutters offer the most efficient method for milling large volumes of long deep grooves particularly when horizontal milling machines are used. Order goods key cutters side and face milling cutters.

Side and face milling. The side and face cutter is designed with cutting teeth on its side as well as its circumference. These cutters are ideal for economic machining of alu. Sales representative will contact you as soon as possible.

The side and face cutters can also be customized to generate required form as per client s description. You will find cutting teeth on its peripheral area and on its sides. They were the most prominent milling cutters in between 1810 to 1880. These are developed using high speed steel of m2 m35 m42 and t42 grades.

Arbor type milling cutters. The growth in vertical milling machines and machining centers however means that end mills and long edge cutters are also frequently used in a variety of groove milling operations.