Sick Light Curtain Safety Relay

In series diagnostics isd is an innovative communication protocol exclusive to banner safety devices that makes it easy to troubleshoot machine.

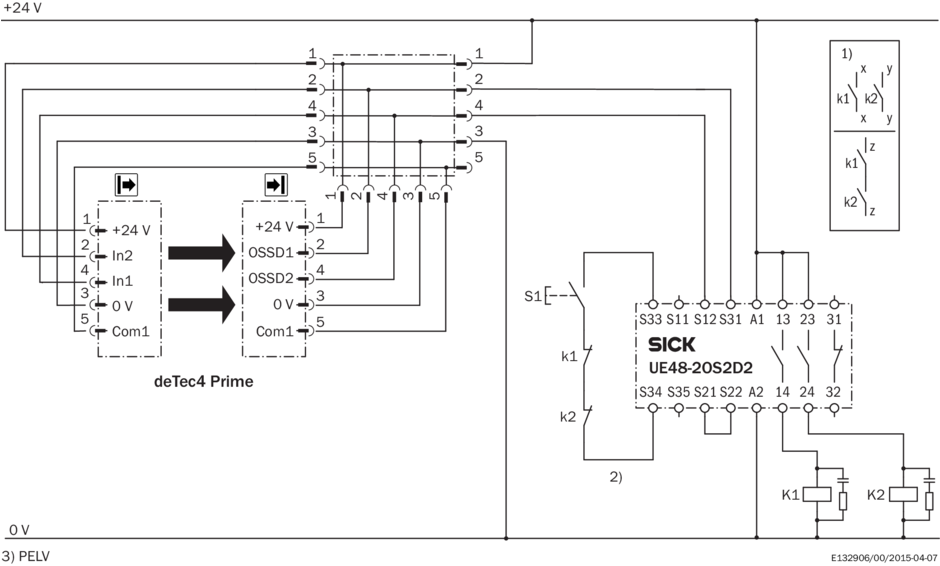

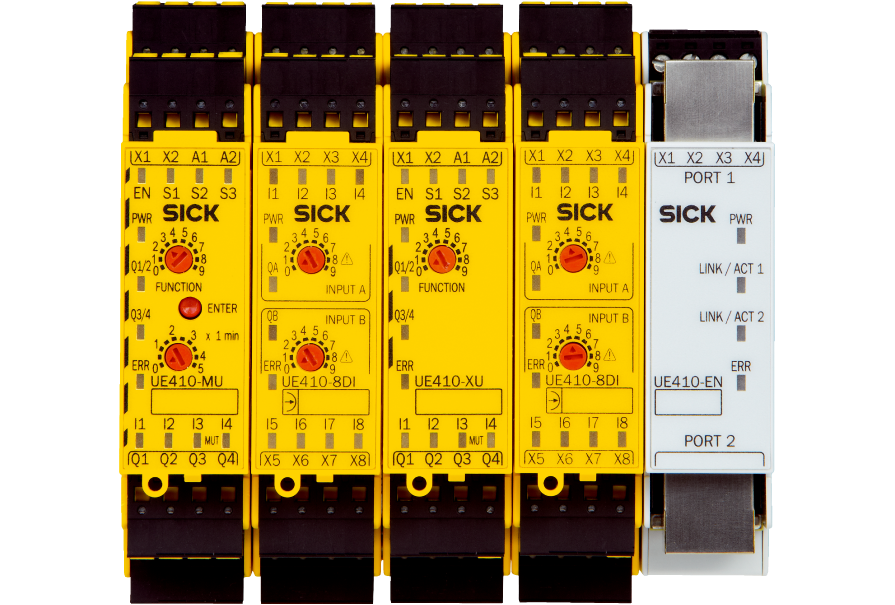

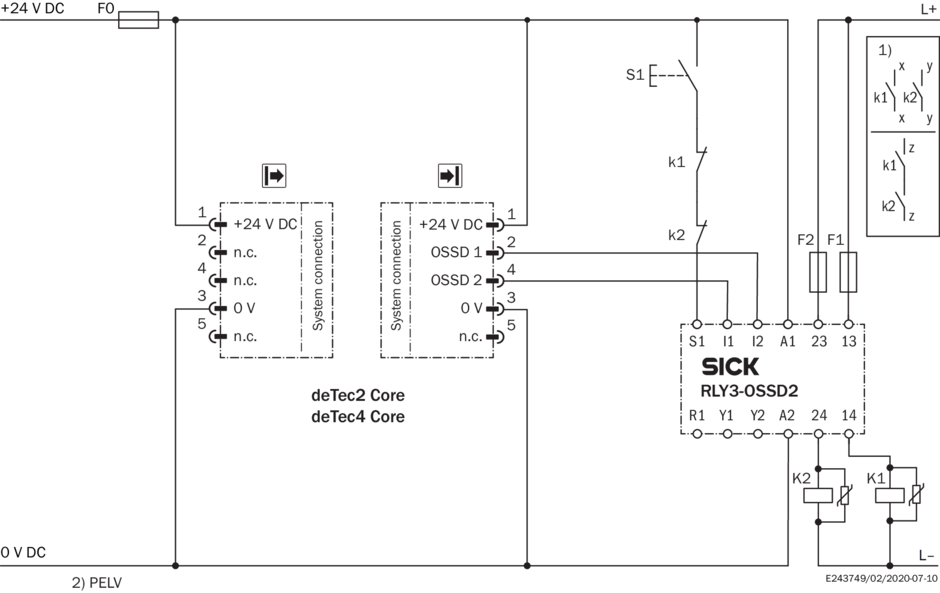

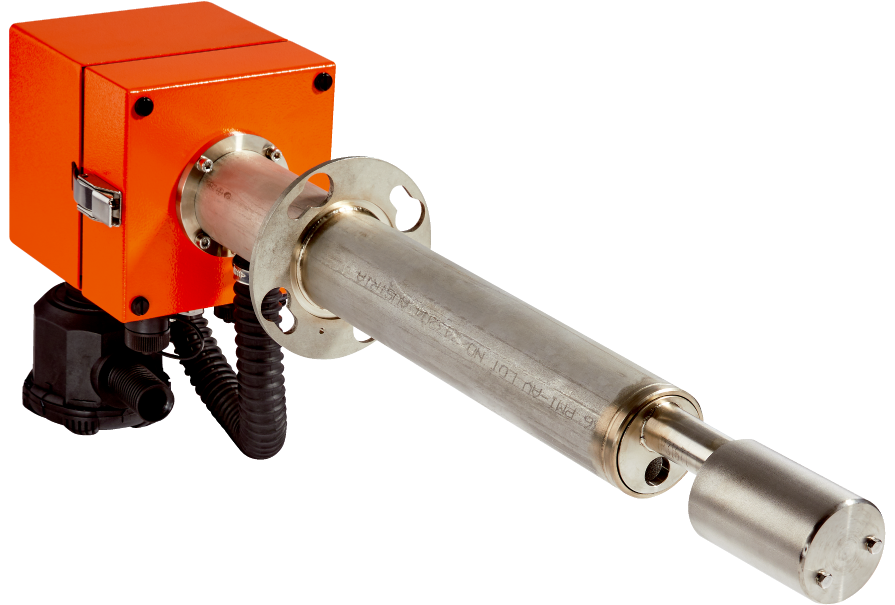

Sick light curtain safety relay. The tasks are so versatile that one light grid cannot fulfill the requirements of every application. Bypass operating mode switching psdi. The wide range of safety solutions from sick from a single channel emergency stop pushbutton to a safety laser scanner with pnp outputs can be connected to safety relays. The range from small and compact types to extremely robust and resistant variants that withstand special ambient conditions up to the highest safety level.

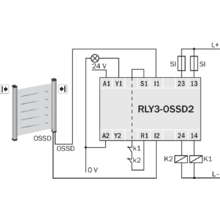

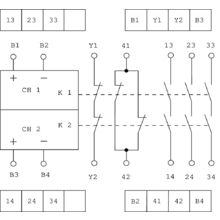

Safety light curtains reliably and cost effectively protect against access into hazardous points and areas. 1211516 order now at sick. Safety relays are ideal for flexible and cost effective machine integration. Timing is the other fault detection method safety relays use.

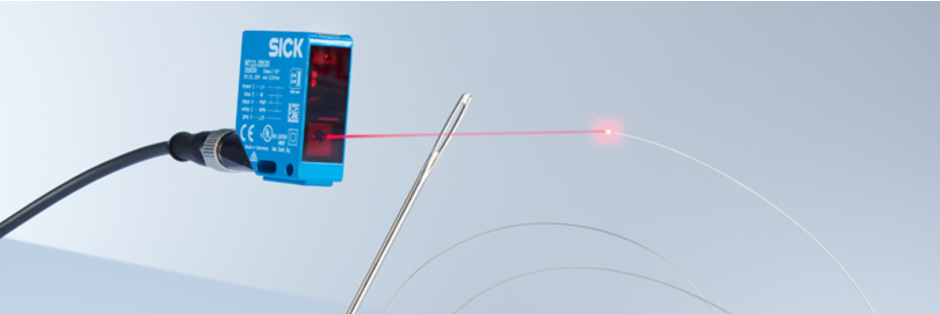

Sick s automation light grids can be used in a number of these solutions such as detecting and counting irregularly shaped objects people and vehicles and checking for presence and pallet overhang detection. At a glance c4000 standard. Safety light curtain detec4. Safety light curtains detec c4c ea09030a10000 part number.

Depending on the variant different machine functions are integrated or can be selected via safe control solutions. System plug sp2. The modular safety light curtain from sick sick ag duration. The new generation of detec safety light curtains is ideal for the protection of hazardous areas entrances and hazardous points.

By measuring flow of current the safety relay checks for welded contact sets and wire breaks. This is all done with timing. Safety relays and safety controllers monitor the primary safety devices that protect personnel from accident and injury ensuring safe stop and start functions on equipment with hazardous motion. The ue402 switching amplifier upgrades the c4000 safety light curtains to include the bypass operating mode switching and psdi functions.

Two dimensional inspection or counting tasks are important in automation.