Shot Blasting Concrete Floor Rental

Shot blasting is a process that is normally done on concrete or metal surfaces.

Shot blasting concrete floor rental. A powerful dust collector vacuum separates the blasted debris from the shot and stores it safely for disposal. Use on interior hard troweled concrete only. When these beads hit the surface they blast off debris and stains that are on the floor which can t be removed through regular cleaning methods. Do not add weight to the machine when operating the tool.

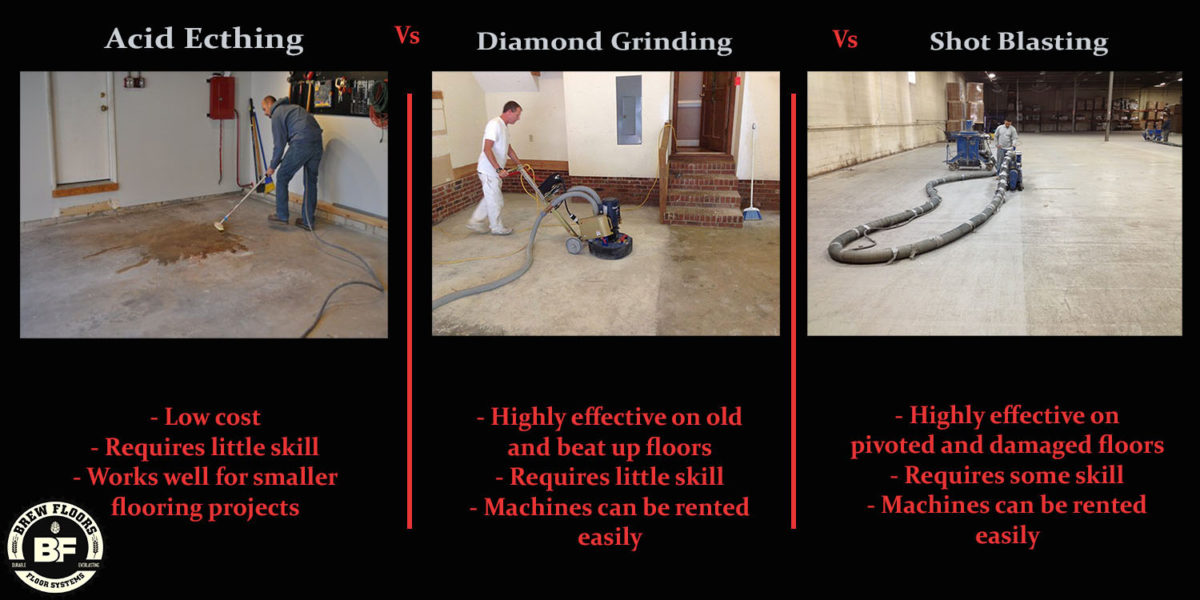

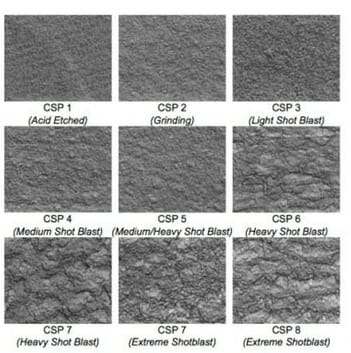

For smaller jobs or jobs where shotblasting just isn t practical grinding is an alternative method to remove coatings and adhesives to prep older flooring prior to the administration of sealers and epoxy coatings for both industrial and commercial surface finishing. Our systems are used by professional contractors and are recommended by coating manufacturers for a wide range of applications. The blasting produces a rough flooring texture that improves adhesion of decorative toppings. The concrete is left with a slightly rough texture that will make it easier to put on a new top and have it adhere.

Portable shot blasters provide one step surface preparation for a variety of concrete surface applications where a minimum amount of material must be removed in preparation for resurfacing. It can be the most productive but it requires the most parts to be replaced. Operate the diamabrush concrete prep tool wet or dry. Shot blasting requires the most attention of the three.

Shot blasting is a one step method for stripping cleaning and profiling floors in preparation for coatings and overlays. Concrete shot blasting machine from procrete resources most shotblasters use a wheel with paddle type blades that propel steel shot at the surface at a high velocity using centrifugal force fracturing off the surface layer of the concrete along with any dirt coatings paint or other contaminants. Etches bare concrete for maximum coating adhesion. Portable shot blasters from sunbelt rentals provide one step surface preparation for a variety of concrete surface applications.

Concrete repair and. Many of the shot blasters available utilize blades that are similar to paddles. Steel beads are shot out of a machine at a very high velocity. When using dry be sure to use a buffer with a dust port and a vacuum to control the dust.

For over 30 years we ve been saving contractors both time and money on jobs like these. Herc rentals 8 inch shot blaster offers excellent mobility and saves operators time on small to midsize applications. In addition the surface is dry after using the shot blaster so the contractors can get to work adding the new floor surface quickly. You scarify diamond grind or shot blast that s how you prep a floor he says.

Shot blasting gives the surface a rough profile so coatings and sealers will bond snugly with a floor.