Shop Floor Production Modeling Software

There are generally three main types of information.

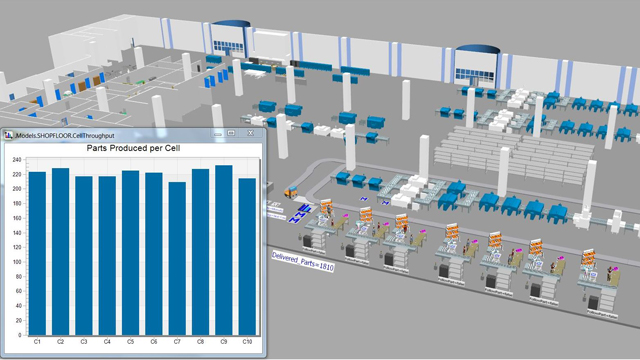

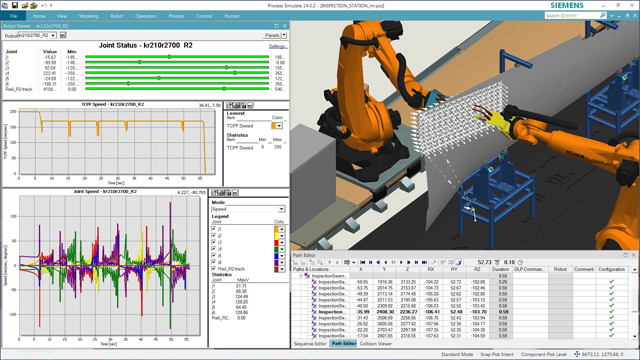

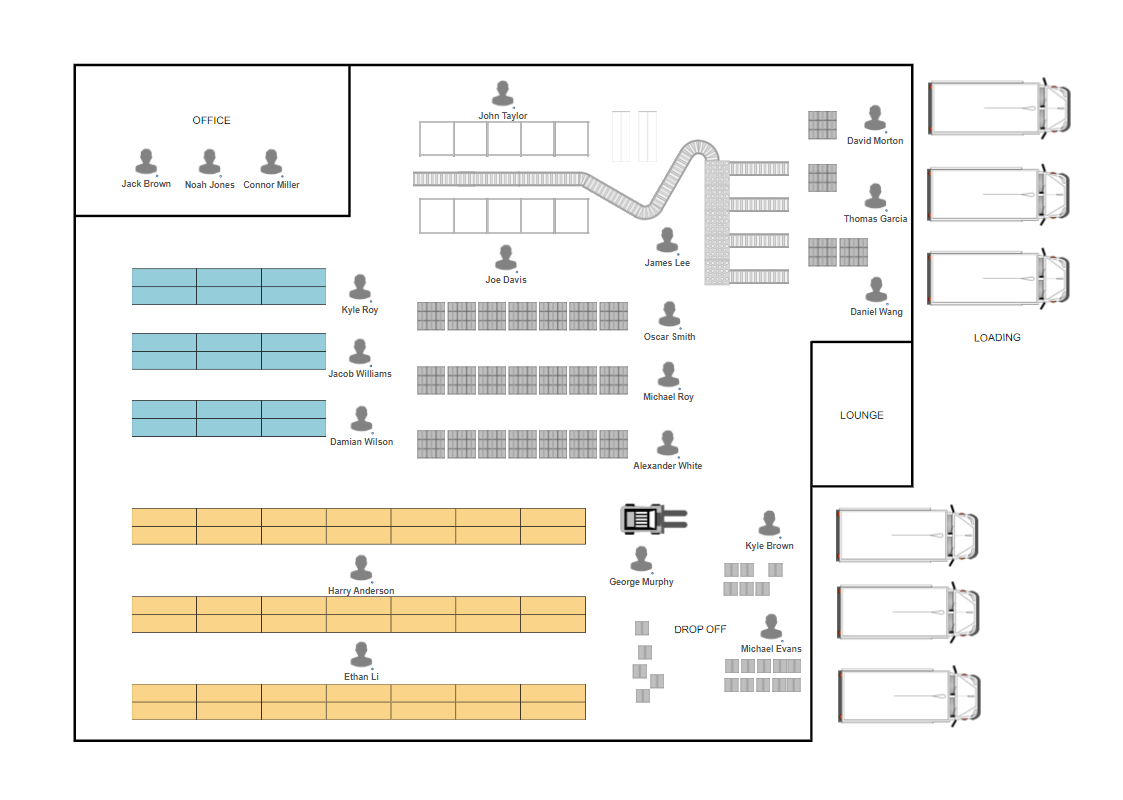

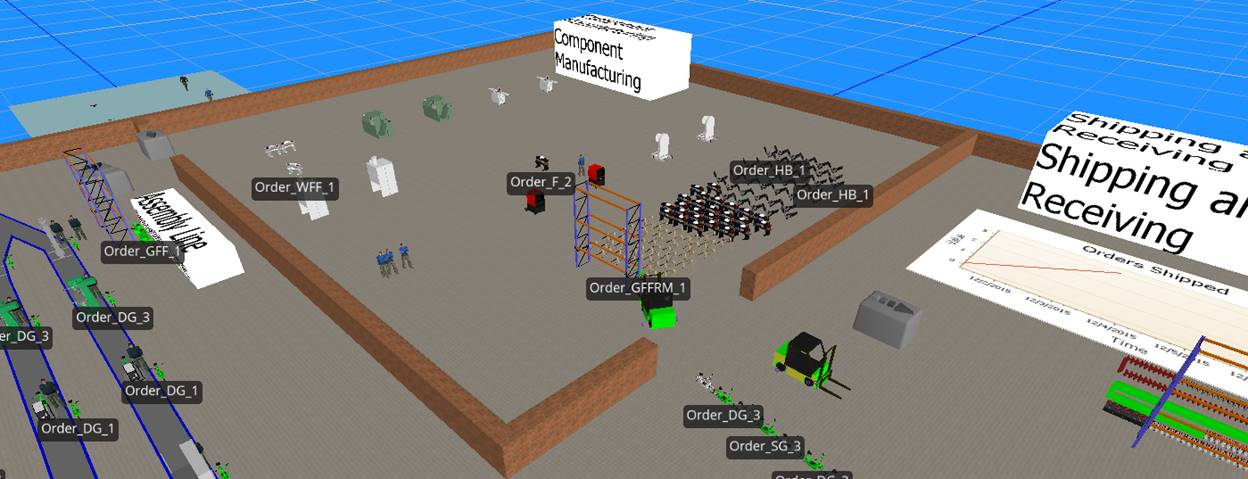

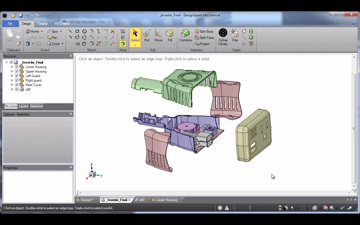

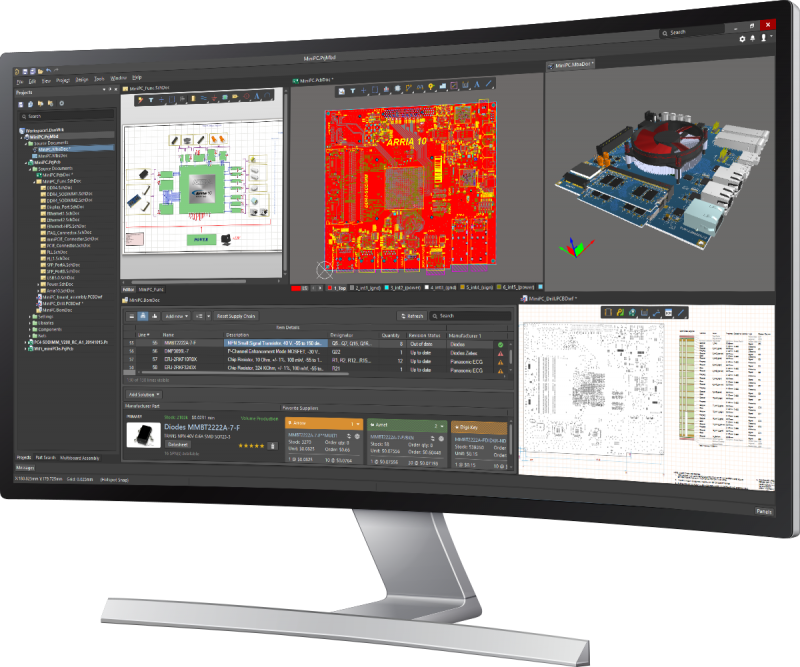

Shop floor production modeling software. The shop floor is responsible to produce an intermediate or a final product. The shop is a complex environment with a high level of variety. Filter by popular features pricing options number of users and read reviews from real users and find a tool that fits your needs. Factory floor communications are used among other things to keep track of equipment placement on the shop floor a factor with a big impact on work flow.

If a job is getting delayed then they may adopt firefighting to avoid late delivery. Utilizing simcad for optimizing production schedules enabled us to achieve a reduction in lead time of 42. With simio simulation and scheduling software you can create optimized scheduling plans that ensure the production process runs without hitches using shop floor data. Quickly browse through hundreds of production scheduling tools and systems and narrow down your top choices.

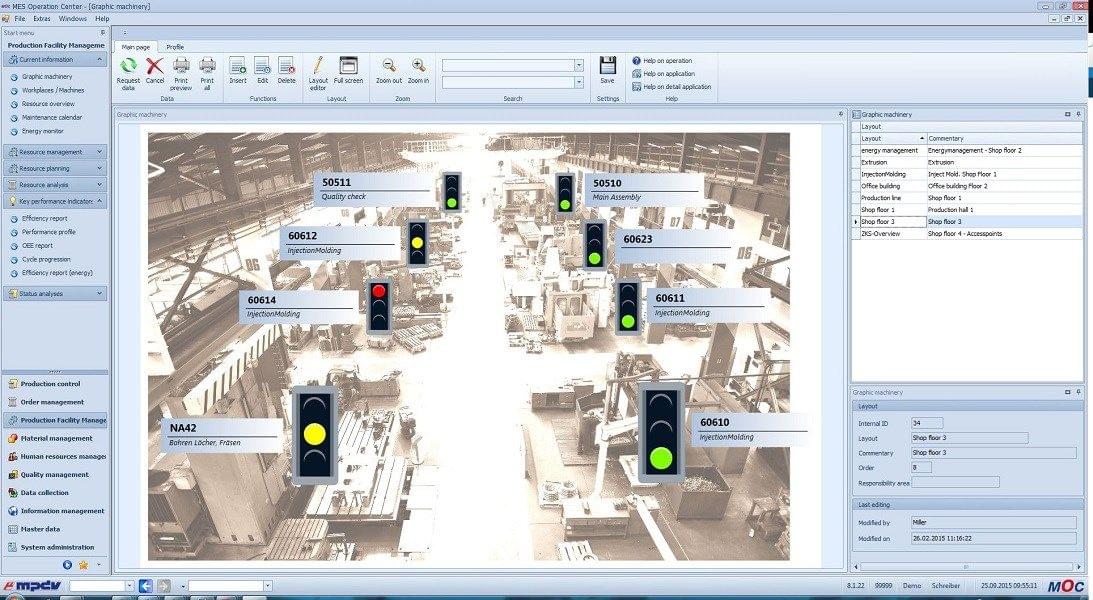

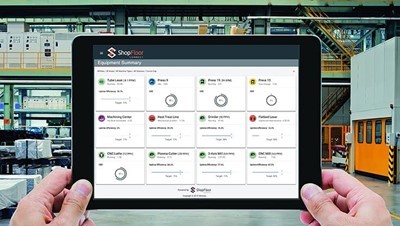

Standardise your shop floor working methods and improve quality and productivity. The data obtained from the system is centrally presented on the shop floor board. Smart shop floor control software should evaluate prioritize manage track and report in real time the necessary and critical manufacturing process. Therefore it is the basis for a smooth workflow and decisions can be made directly on site.

The shop floor may include equipment inventory and storage areas shop floor is the place where design specifications are referred machinery and manufacturing equipment are employed for production parts are assembled or some raw material is processed. Your schedulers are therefore critical in finding key opportunities to improve your production results. You can also evaluate advanced plans such as the effects of a new material handling system to operations before implementation. If a model does not reflect changes in equipment placement which may change on a time scale of hours the model s output relevant to making work flow decisions may well be incorrect.

The nature of our product is very variable and job priority constantly fluctuates. A high quality manufacturing execution system will also provide the best tools for controlling the scheduling needs directly on the shop floor. Find and compare top production scheduling software on capterra with our free and interactive tool. In the simultaneous production of diverse jobs using shared resources of finite capacity the real time decisions for scheduling heterogeneous workload on shop floor will have a domino effect on production and that effect cannot be easily predicted.

The information flow is actuated by the shop floor management. Shop floor management offers different advantages in production planning.