Shop Floor Data Capture Software

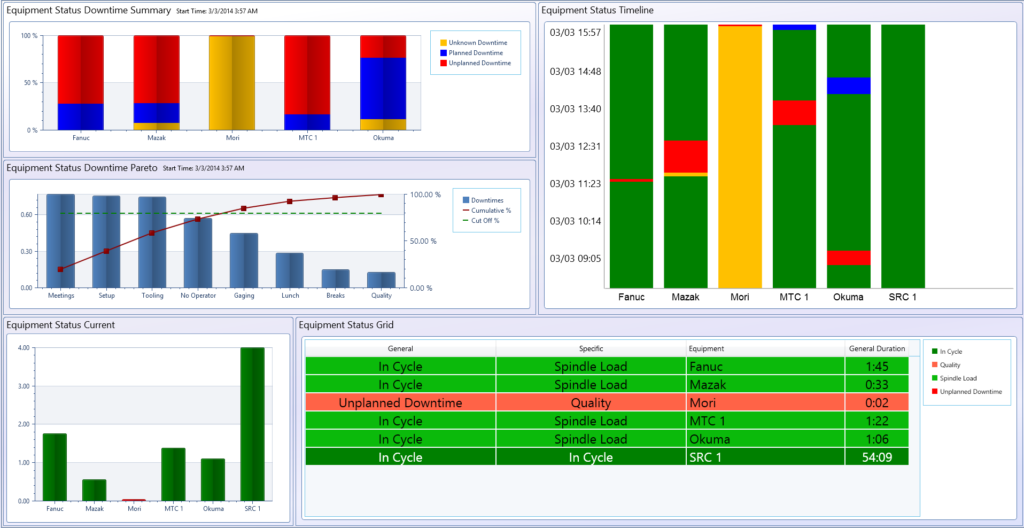

Iqms offers two different realtime manufacturing monitoring options for your shop floor.

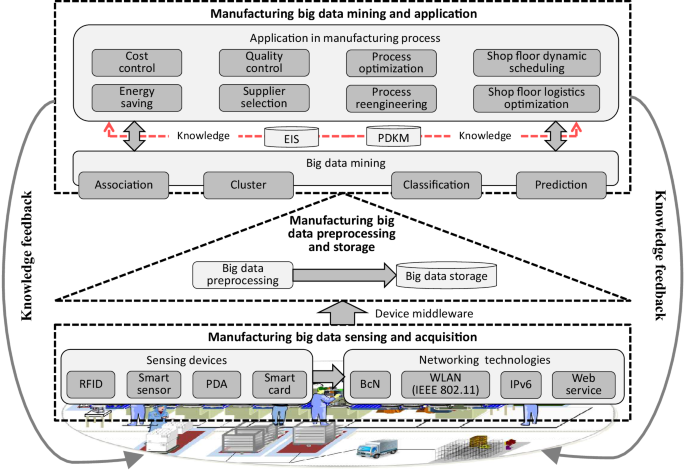

Shop floor data capture software. Data is input using shop floor based data capture pcs optionally equipped with bar code readers and touch screens. Plantrun collects data directly from your manufacturing assets machines equipment plc s and from operator keypad or touch screen terminals barcode scanners rf readers etc. Allows job data to be entered on shop floor. Sfdc provides users with accurate work in progress and costing information while simultaneously minimising administrative input and clerical errors.

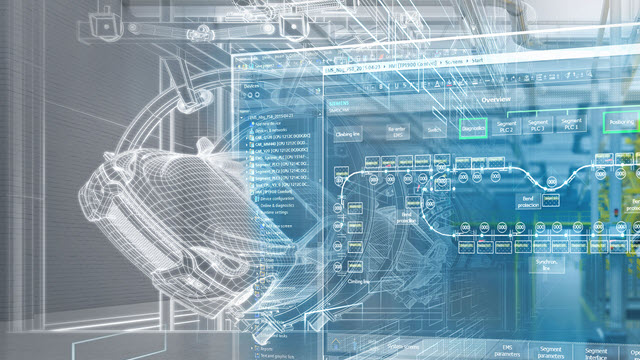

Take control of your manufacturing floor activity with the shop floor data collection application in your global shop solutions erp software. Seiki air jobpack dnc and manufacturing data management software is an easy to use and maintain shop floor communications and nc program transfer solution. Si s shop floor data capture applications run on touchscreens and intelligence scanners to allow for data capture throughout the production cycle from intake all the way through to finished goods production and across all operational processes and stock traceability as products are stored recorded and labelled. Through our modular approach an si mes solution is built to fit your business.

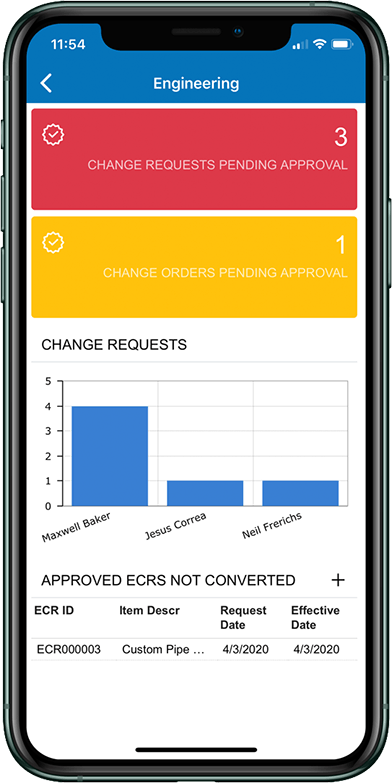

Shop floor data capture provides users with accurate work in progress and costing information while simultaneously minimising administrative input and clerical errors. The add on for dynamics 365 business central utilizes barcoded production orders to simplify data capture on the shop floor and reduce the errors associated with manual time entry. Shop floor employees clock in and out of jobs machines and your facility providing you real time and accurate data on labor and production costs. Sort and export any screen real time or archived into excel pdf and more.

Plantrun shop floor data collection systems provide accurate real time information and have been used by manufacturers for over 25 years. Mes shop floor data capture si has spent almost three decades perfecting our range of world class modular food erp and mes software. It offers a single source solution for all your cnc machines. Shop floor insight is a comprehensive solution for barcoded time capture time and attendance and employee time management.

Real time feedback of production progress. Plc based process monitoring and machine to machine m2m interface iqms realtime process monitoring system provides an in depth look into your processes and can be utilized on any device or machine with data communication capability such as a programmable logic controller plc. As your business grows so can your si food erp by adding from our wide range of modular food software.

.jpg)